Pulleys crown

To prevent the flat belt from slipping, at least one pulley must be crowned, preferably a larger pulley or a pulley with the greatest contact angle.

Usually the available pulleys are crowned to ISO 22. The greater the contact angle, the better the following effect of the belt.

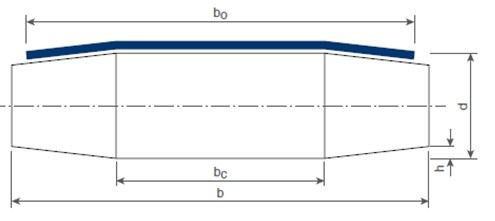

In practice, based on the total length of the drum, the typical design of a crown pulley is applied to three equal parts (conical / cylindrical / conical).

Pulley width

The pulley width should be at least 1.05-1.1 times that of the belt. In principle, we recommend that half of the wide belt be cylindrical and conical.

Roller surface

The clean, smooth steering surface improves the efficiency and durability of conveyor belts.

The working surface of the mobile pulley must not be too smooth or too rough (the surface must not be wrinkled!), As this can cause excessive belt wear, noise and premature belt failure.

It is recommended to make a work surface with a roughness Ra = 1.6μ-3.2μ-6.3μ.

Drive of the pulley design conveyor belt: Calculation

Length of cylindrical area bc

bc = bo / 2

Pulley width b

b = bo x 1,1

Crown bow h

h = (d + 100) / 450 mm